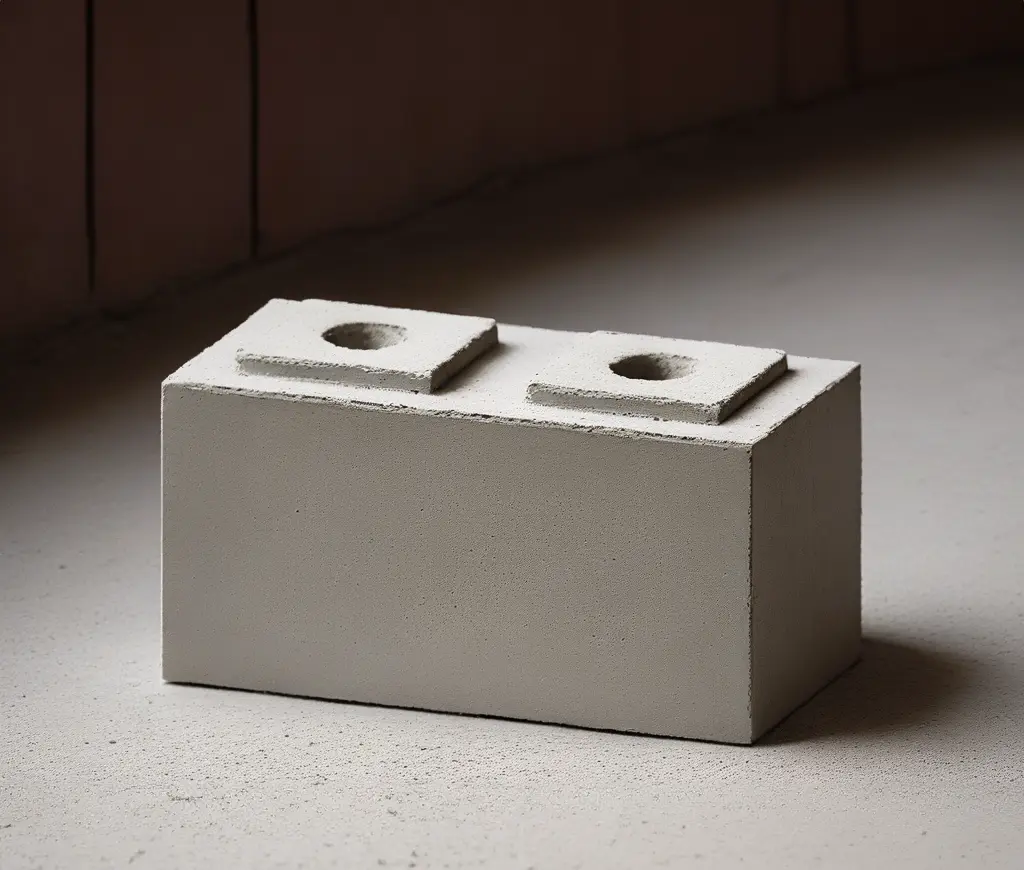

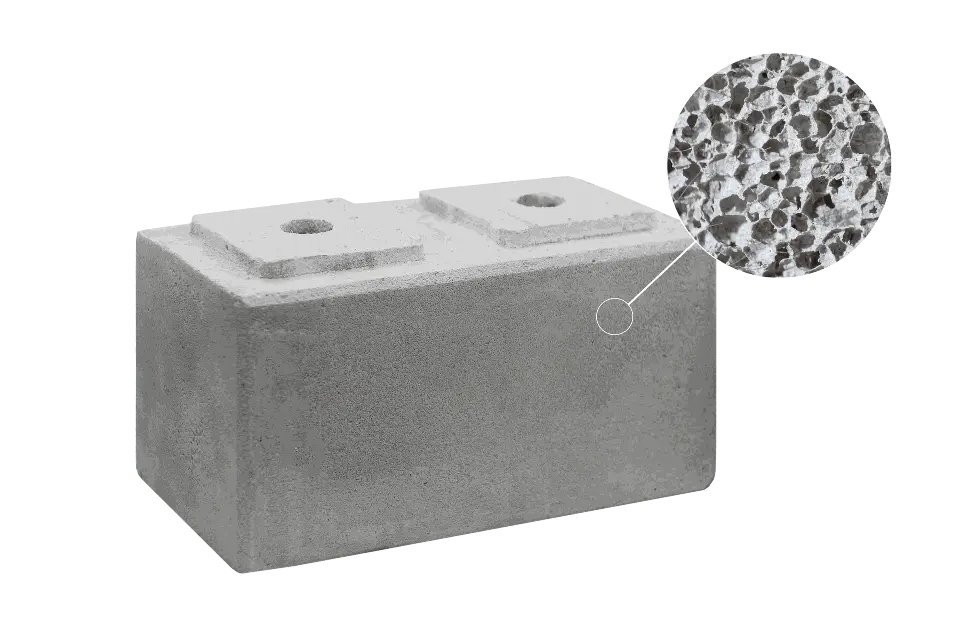

What is V-Lite Lightweight Concrete Block?

V-Lite ultra-lightweight concrete blocks are made from CLC (Cellular Lightweight Concrete) combined with a unique interlocking design, significantly reducing weight compared to traditional bricks. With an air bubble structure occupying 40% to 80% of its volume, V-Lite blocks offer superior thermal insulation, soundproofing, and fire resistance. This product not only reduces the load on foundations but also helps save construction costs and accelerate progress, making it ideal for green and sustainable building projects.

Lightweight, Easy to Build

V-Lite blocks are lightweight, reducing the load on building structures and saving construction costs. Their three-dimensional interlocking design ensures quick and precise assembly, making them ideal for lightweight concrete walls, exterior walls, and partitions in high-rise buildings and industrial facilities. This feature is especially valuable for projects where reducing weight and saving time are critical.

Superior Insulation, Soundproofing, and Waterproofing

V-Lite blocks offer excellent thermal insulation, maintaining stable indoor temperatures and reducing energy costs for heating and cooling. Their superior soundproofing minimizes external noise, ensuring a quiet and comfortable living space. Additionally, V-Lite’s waterproof properties make them an ideal choice for social housing and rental projects, where quality and affordability are top priorities.

Cost-Effective and Sustainable

Compared to traditional fired bricks, V-Lite blocks significantly reduce material and labor costs. With no need for thick plaster, just a thin 1-2mm skim coat, they save both time and finishing expenses. Their high fire resistance and long-lasting durability ensure safety for both buildings and residents. This makes V-Lite blocks an ideal choice for residential and commercial constructions where cost efficiency and safety are top priorities.

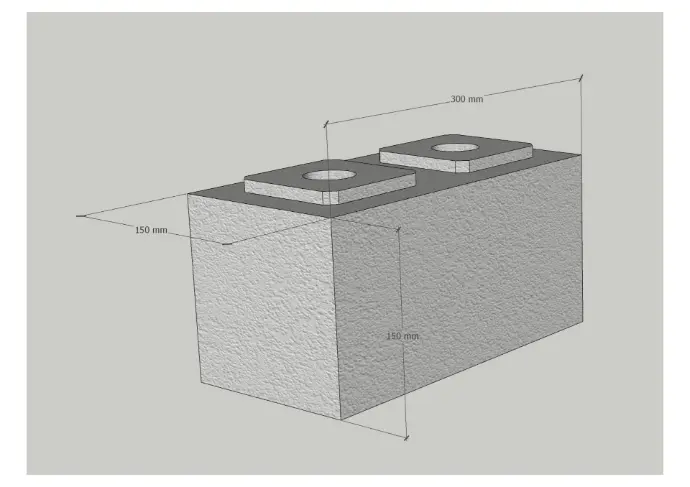

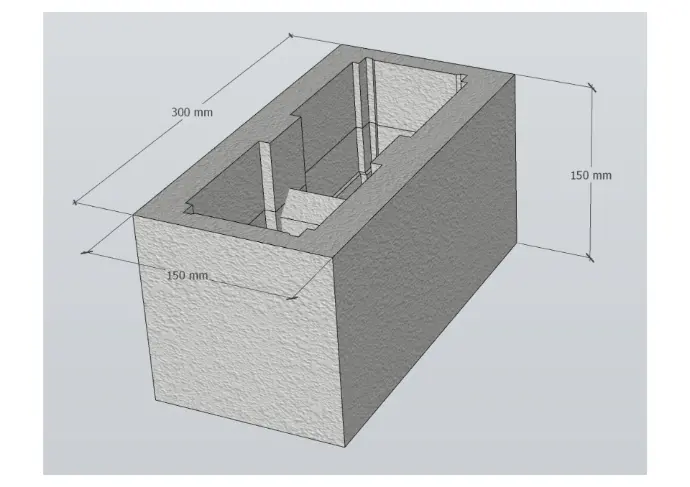

Technical Specifications

Dimensions | 300 x 150 x 145 mm |

Average Mass | ~4,5 kg |

Density | 660 kg/m³ |

Compressive Strength | Minimum 4 N/mm² |

Load-Bearing Capacity | 85.800N (8,7 tấn lực) |

Dry Shrinkage | ≤ 0,2% |

Water Absorbtion | 0.7 lít/m².hr |

Advantages of V-Lite Lightweight Blocks

Lightweight

Reduces load on foundations and structure, optimizing construction costs.

Excellent Thermal and Sound Insulation

Maintains stable indoor temperatures and minimizes external noise.

Waterproof and Fireproof

Protects buildings against harsh environments and enhances safety.

Cost-Effective

Minimizes material waste and labor costs.

Applications in Construction

Explore the diverse applications of V-Lite interlocking foam concrete blocks in modern construction, from exterior walls of high-rise buildings to projects requiring superior thermal insulation, soundproofing, and waterproofing. V-Lite blocks ensure optimal efficiency and sustainability for every structure.

House Walls and Exterior Walls

V-Lite blocks are ideal for constructing house walls and exterior walls of high-rise buildings due to their lightweight nature and high load-bearing capacity. They help reduce the structural load, enhance thermal and sound insulation, and speed up the construction process, ensuring a strong and durable wall system.

Residential and Industrial Construction

V-Lite blocks are ideal for both residential and industrial construction projects, such as houses, factories, and warehouses. With excellent fire resistance, waterproof properties, and energy efficiency, these blocks ensure safety and durability. The lightweight design simplifies transportation and installation, reducing labor costs and accelerating project timelines.

The Ideal Solution for High-Rise Buildings

V-Lite blocks are a perfect choice for high-rise constructions due to their lightweight design, which significantly reduces the load on foundations. The interlocking feature ensures precise and fast assembly, minimizing construction time and costs while maintaining structural integrity. Additionally, V-Lite blocks offer excellent insulation, soundproofing, and waterproofing capabilities, making them an efficient and durable solution for modern multi-story projects.

Steel-framed prefabricated and modular houses,

V-Lite blocks can be used for building steel-framed prefabricated and modular houses, helping to save time and construction costs while ensuring high-quality structures.

Building soundproof walls for entertainment facilities.

V-Lite blocks are ideal for constructing soundproof walls in entertainment facilities such as cinemas, theaters, and recording studios, ensuring a quiet environment and superior sound quality.

Application in green and sustainable projects.

V-Lite blocks are the perfect choice for green and sustainable construction projects, thanks to their energy-saving capabilities, reduced CO2 emissions, and use of eco-friendly materials. This makes V-Lite blocks an ideal solution for architectural designs that demand green building materials.

Easy Installation with V-Lite Blocks

Quick & Simple Installation Like Building Lego Bricks

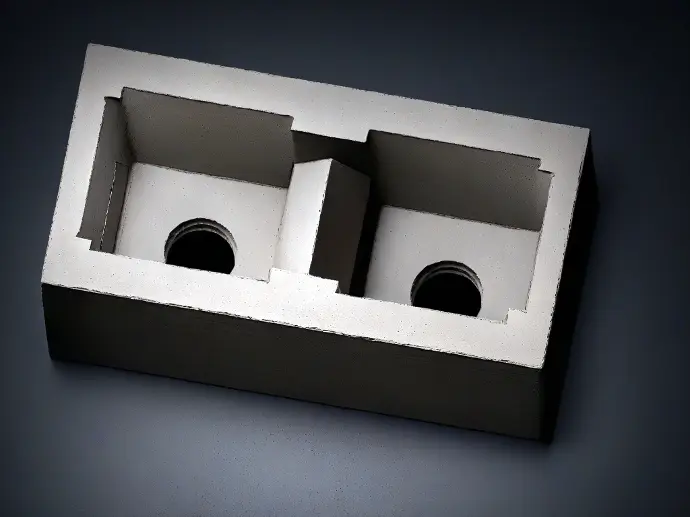

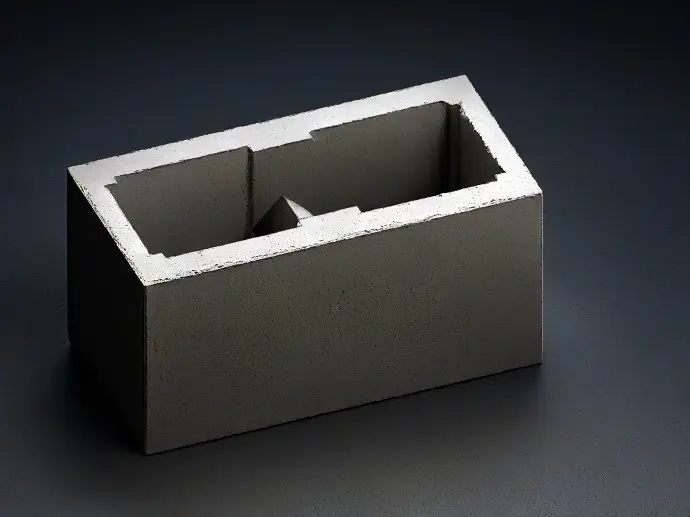

V-Lite blocks are designed with a three-dimensional interlocking system, similar to assembling Lego bricks. This feature makes it easy and precise to stack the blocks without requiring highly skilled labor. Users can build walls with minimal mortar, reducing the risk of cracking caused by excessive mortar layers.

Saving Materials and Labor Costs

V-Lite’s innovative interlocking design reduces mortar usage to just around 10% compared to traditional bricks and AAC blocks. This not only saves materials but also lowers labor costs due to faster installation. A single 25kg bag of dry mortar can be used to build an entire large wall. In fact, with V-Lite blocks, you can even build walls without using any mortar at all.

Flexible Construction Solutions

V-Lite blocks allow contractors to construct structural elements such as beams, wall ties, columns, and lintels without the need for formwork, by utilizing the hollow core within each block to embed reinforced concrete components directly into the wall. This significantly saves both time and construction costs. Additionally, installing utility systems like piping and electrical cables is much easier, as it can be done without chiseling into the walls, making the construction process more convenient overall.

V-Lite Production Process

Concrete Mixing

Produced at Automated Concrete Plants with Specialized Additives

Pouring Mortar

Concrete mixture is then poured into molds

Cutting

Concrete cake is then cut into blocks after being set for 3-4 hours

Curing

Overnight curing

& Molds removal

Finished

Blocks are stacked onto pallets & ready to ship

The product has been officially registered for intellectual property rights protection.

Bằng độc quyền số 37559 của Cục Sở Hữu Trí Tuệ, cấp ngày 17/11/2023

Partnership Opportunities with THT International

With immense growth potential in the construction market, this is a golden opportunity to expand scale and ensure sustainable growth. Partner with us to lead the future of construction with V-Lite and unlock new business opportunities!

Why foam concrete?

Lightweight

Reduces structural load and construction costs while being easy to transport and install.

Exceptional sound & heat insulation

Maintains stable temperatures and reduces external noise, creating a comfortable and quiet living space.

Fireproof and waterproof

Enhances safety and protects buildings from moisture, extending their lifespan and ensuring high construction quality.

Energy saving

Reducing energy demand for heating and cooling systems, contributing to environmental protection and lowering operating costs.

Frequently Asked Questions

V-Lite blocks are designed with a Lego-like interlocking structure, making construction faster, more precise, and reducing labor costs. They are lighter yet offer high load-bearing capacity, along with excellent thermal, sound insulation, and waterproof properties, ensuring durable and energy-efficient buildings.

V-Lite and AAC blocks are both lightweight, but they differ mainly in production processes and features:

- Production Process: V-Lite blocks are made using foam concrete technology, creating a closed-cell structure that reduces water absorption. In contrast, AAC blocks use autoclaving, which can lead to higher porosity and moisture absorption.

- Durability and Flexibility: V-Lite blocks feature a robust structure that eliminates the need for formwork when constructing beams, lintels, and columns. This enhances load-bearing capacity, making them an ideal choice for high-rise buildings.

- One of the drawbacks of AAC blocks is their high water absorption. Due to their air bubble structure and autoclaved production process, AAC blocks tend to absorb moisture easily, especially in humid conditions. This can lead to wall cracking, reduced structural quality, and increased maintenance costs. In contrast, V-Lite blocks have a closed-cell structure that offers superior water resistance, keeping walls dry and durable—making them especially suitable for high-rise buildings.

V-Lite blocks are ideal for a wide range of projects, including high-rise buildings, residential and commercial structures, prefabricated houses, and partition walls. Their lightweight and durable properties help reduce structural load, lower construction costs, and improve energy efficiency, making them perfect for sustainable construction projects.

Yes, V-Lite blocks are suitable for extreme climates. Their closed-cell structure offers excellent thermal insulation, helping to maintain stable indoor temperatures in both hot and cold conditions. Additionally, V-Lite blocks are resistant to moisture and water infiltration, preventing damage in humid or rainy environments, making them ideal for diverse climate conditions.

Yes, V-Lite blocks are environmentally friendly. They are made from lightweight foam concrete using recycled materials, reducing resource consumption and CO2 emissions. Additionally, their excellent thermal insulation properties help save energy in heating and cooling, contributing to a sustainable and eco-friendly construction approach.

The compressive strength of V-Lite blocks is at least 4N/mm², ensuring durability and excellent load-bearing capacity for high-rise buildings and other demanding construction projects.

Yes, using V-Lite blocks can significantly save costs. Their lightweight design reduces structural load, minimizing foundation expenses. The self-locking feature cuts down on mortar use and labor costs by speeding up installation. Additionally, their superior insulation properties help lower energy costs for heating and cooling, making V-Lite blocks a cost-effective choice for sustainable construction projects.

V-Lite blocks have excellent fire resistance due to their closed-cell foam structure, which prevents fire from spreading and withstands high temperatures for extended periods. They meet strict fire safety standards, making them ideal for residential and industrial buildings. The fire resistance of V-Lite blocks ensures enhanced safety for structures, protects occupants, and minimizes damage during a fire.

V-Lite blocks with a closed-cell foam structure offer excellent soundproofing capabilities, making them ideal for buildings that require quiet environments, such as cinemas and recording studios.

You can purchase V-Lite blocks by visiting our official website or contacting our hotline for detailed consultation. Alternatively, you can fill out the contact form on the website to receive a quote and prompt assistance from the THT International team.

-

-

-

Interested in V-Lite blocks for your project?

Contact us today to receive the best solutions and expert advice from our top specialists!